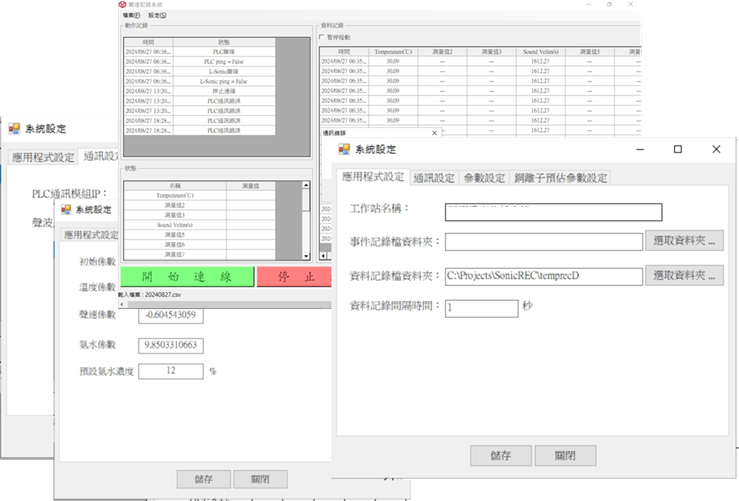

Application

Traditional manual control methods are difficult to implement; therefore, through our AI data computation model, accurately controlling these parameters is crucial to ensuring product consistency and improving production efficiency. By collecting and analyzing real-time data, the model can accurately predict and adjust the mixing ratios and conditions of the chemical reaction process, keeping the metal ion concentration within the optimal range. This model utilizes historical data and real-time process parameters for deep learning, enabling rapid identification and adjustment of factors that affect product quality.

Feature

Promptly Response:

Real-time monitoring and adjustment continuously track the key indicators throughout the production process, detecting any process changes and maintaining a stable production environment.

When the system detects anomalies or changes, it can immediately adjust parameters and take action to restore stability, improving production efficiency, reducing resource waste, and ensuring product quality consistency.

Enhance Quality:

The AI model adjusts the mixing ratio in real-time, ensuring the metal ion concentration meets quality standards. It can quickly analyze the current mixing conditions and automatically calculate the necessary adjustments to respond to various environmental changes and material fluctuations. This not only improves product quality and stable supply but also reduces the need for manual intervention.

Reduce Cost:

By accurately controlling the chemical reagent input, material waste is minimized, and production costs are reduced. The system continuously monitors the changes in chemical reactions and automatically adjusts the reagent dosage based on reaction progress and demand. By learning from past data and feedback, the system optimizes formulations and input strategies, improving input accuracy and ensuring cost control at every stage of production.

Improve Efficiency:

Real-time adjustments to process parameters reduce defective products and enhance overall production efficiency. Through real-time data monitoring, the system continuously tracks key indicators in the production process, quickly identifying any deviations from standards. Once an anomaly is detected, the system automatically adjusts related process parameters, such as temperature, pressure, or mixing time, to ensure the production process remains in optimal condition.