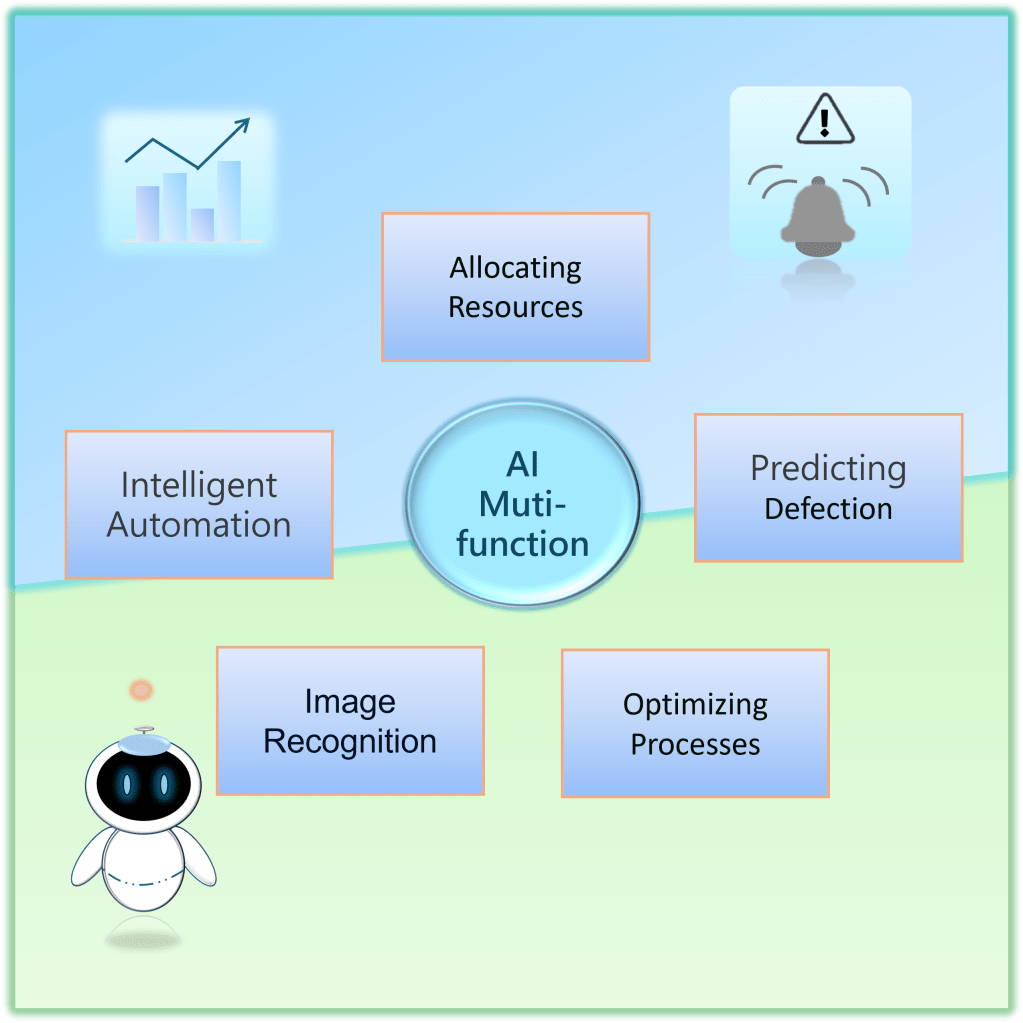

The application of Artificial Intelligence (AI) in various factories is rapidly evolving, mainly in production process optimization, equipment failure prediction, and quality control. Through data analysis combined with automation technology, AI facilitated the realization of smart manufacturing, quickly responded to market demands and improved flexibility. In the future, AI will further drive corporate transformation, creating new business models and the developing opportunities.

Introducing AI-driven smart manufacturing can significantly enhance production efficiency and product quality. Through machine learning and data analysis, AI can monitor the production process in real-time, predict equipment failures, and reduce downtime and maintenance costs. Intelligent quality control systems can instantly detect defects, ensuring product consistency. Additionally, AI can optimize inventory and forecast demand changes in supply chain management, further reducing operational costs. With AI implementation, companies can also increase production flexibility, quickly respond to market changes, and strengthen competitiveness. Overall, smart manufacturing not only boosts economic benefits also drives digital transformation and innovation.