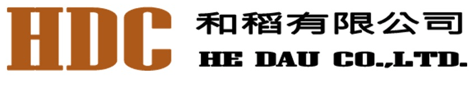

IIOT: Creating the future of intelligent production and management energy

With application of progressive technologies, IIOT is re-creating the role in intelligent factories and low- emission project of traditional industries. It can instantly collects the operation, the consume, the temperature, OEE…. in any equipment through the sensors and real time analyze data. Then, monitoring, predicting and remaining the situation of the equipment and warning the potential problems and controlling more accurate and tracking the inventories to improve efficiency and to reduce costs.

The core of IIOT is to raise energy, equipment and management, making reduce the operation costs and keep development and apply EMS, OEE and AOI.

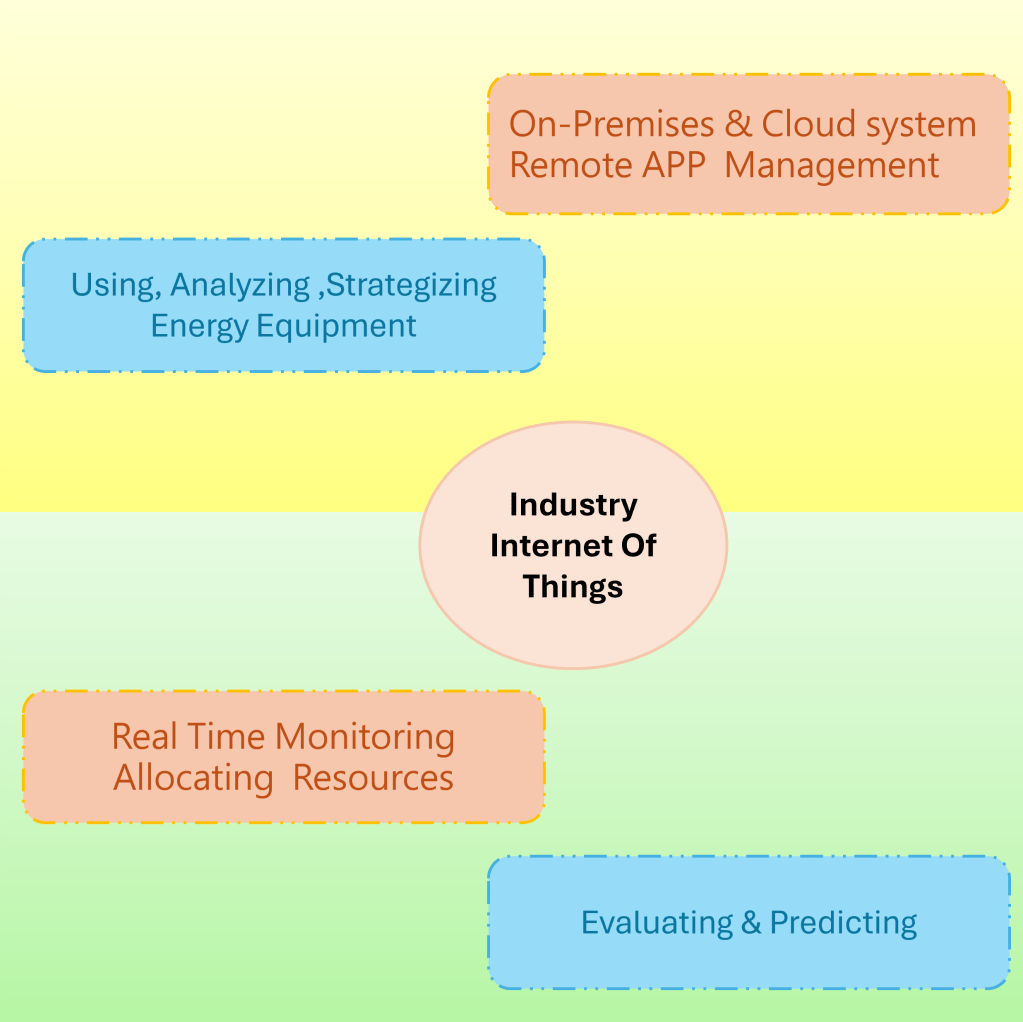

EP100: Raising Intelligent Production

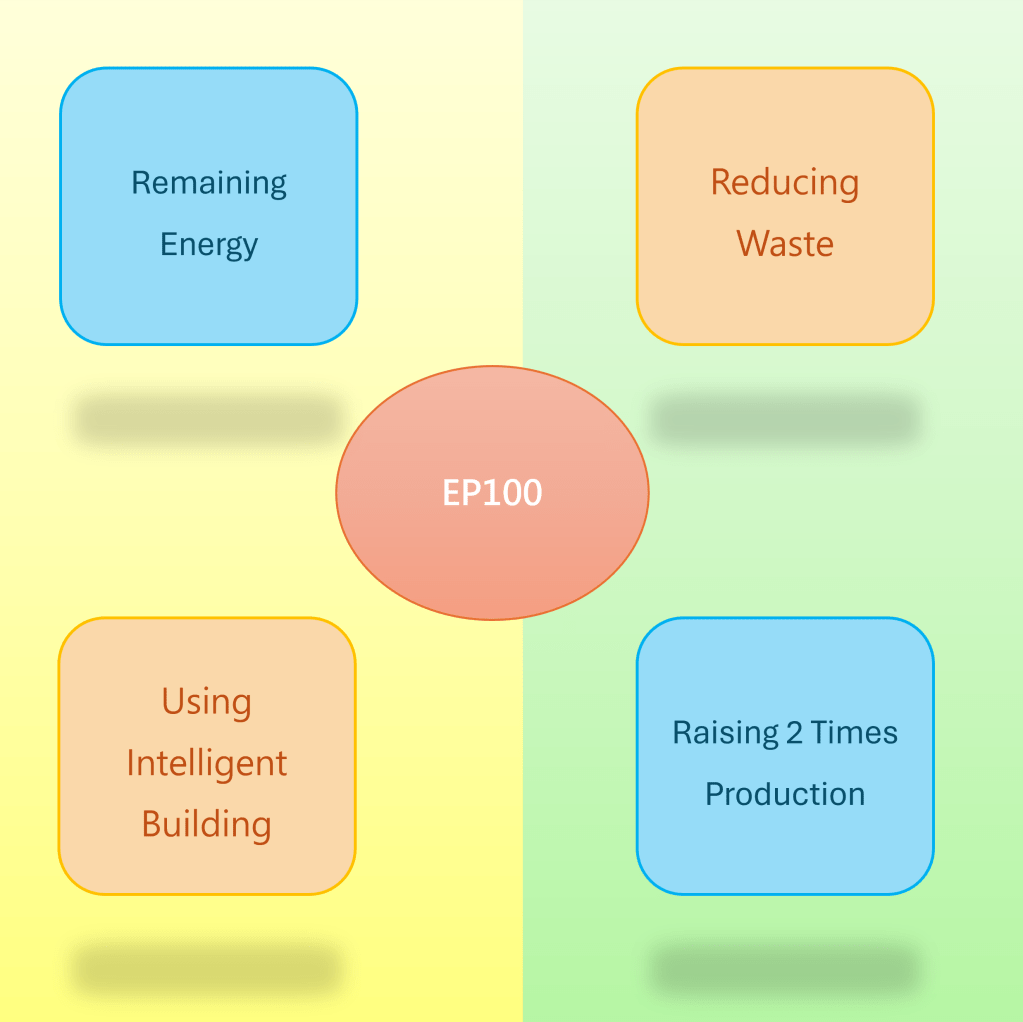

Government encourages the saving energy and provide the relative subsidy to drive the enterprise reduce invest costs and achieve intelligent management. It enables to monitor the situation of the equipment, collect and analyze data of power and find abnormal to improve, through the indexes, the warning management, dashboard, the reports of EMS system. Those easily control the progress and the resource of production.

The Experience: Integrating EP100 And IIOT in Textile Industry

To promote the international competition, a textile company executed EP100 plan to resolve the difficult of OEE and problems of using efficiency, therefore, it build OEEs system and EMS system to integrate the intelligent tools.

Building an accumulation for real time collecting data from sensors and delivering to OEE and EMS which provide the trends and the strategies of analyzing and warning, it can eliminate the bottleneck and the waste. Resulting in improving overall using efficiency and production and reducing the costs and raising the benefit and the international position.